ExxonMobil Guyana Hammerhead Project to use Proxxima™ Technology

ExxonMobil’s Hammerhead Project will leverage the Proxxima™ resin system-enabled Goldilocks (GDLX™) technology (Proxxima-GDLX) as the insulation solution for 11 km of subsea water injection pipelines and production flowline jumpers. It will be one of the most significant new oil and gas production initiatives globally.

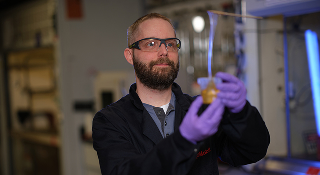

Proxxima resin systems simplify the traditional multi-layer insulation process, bringing multiple layers of insulation down to one. For the Hammerhead installation, this translates to faster application and project schedule benefits while improving the durability that deepwater environments demand.

“There’s no stronger validation than using Proxxima solutions in our own operations,” said Matt Loach, ExxonMobil’s General Manager for the Proxxima brand. “This application reflects the confidence we have as a corporation in the value proposition of Proxxima technology in this application.”

This application marks the first use of Proxxima technology in a mid-temperature (95-135°C) subsea oil and gas application, building on its successful deployment in high-temperature environments (135°C +) by other global operators.

In this project, the Proxxima-GDLX solution will allow for novel direct-to-steel technology, functioning as both an insulator and corrosion barrier, thereby eliminating the need for additional anti-corrosion layers – reducing cost without compromise.

“This is a game-changer for subsea insulation,” said Tanmay Desai, CEO of ODYSEA. “By using Goldilocks, enabled by the Proxxima technology, we’re delivering to the industry a faster, more efficient and higher performing insulation option for flow lines, field joints and other critical components."

ExxonMobil recently announced plans to license the Proxxima-GDLX solution to other companies insulating subsea infrastructure.

Related content

What is Proxxima

Markets