ExxonMobil implements APC’s TriFLEX™ technology leveraging Proxxima™ systems at Beaumont facility, cutting application time, VOCs, and costs

- ExxonMobil is an early adopter of TriFLEX™ technology which incorporates its own Proxxima™ polyolefin thermoset resin system

- A pilot project was recently completed using APC’s TriFLEX™ coating system for piping at ExxonMobil’s Beaumont Refinery

- The formulation delivered superior results through streamlined operations, reduced VOCs, excellent protection and enhanced cost-efficiency

- ExxonMobil is an early adopter of TriFLEX™ technology which incorporates its own Proxxima™ polyolefin thermoset resin system

- A pilot project was recently completed using APC’s TriFLEX™ coating system for piping at ExxonMobil’s Beaumont Refinery

- The formulation delivered superior results through streamlined operations, reduced VOCs, excellent protection and enhanced cost-efficiency

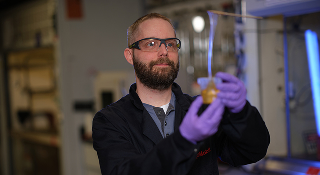

ExxonMobil Product Solutions Company, a division of Exxon Mobil Corporation (ExxonMobil), has successfully completed a pilot program using the TriFLEX™ coating formulation from Advanced Polymer Coatings (APC) within the Beaumont Refinery in Texas. This milestone marks the TriFLEX™ coating formulation’s expansion into atmospheric industrial piping—one of several emerging applications. The coating formulation incorporates ExxonMobil’s proprietary Proxxima™ polyolefin thermoset resin system, enabling APC to engineer a high-performance, single-coat solution tailored to the rigorous demands of industrial asset owners like ExxonMobil.

“In our industry, certainty drives success,” said William Handy, Coatings Segment Manager for the Proxxima business. “Every day saved in the coatings process matters—because the finish line is only reached when every element aligns. That’s where Proxxima systems stand out: they streamline complexity and help projects stay on schedule.”

One of the key advantages of Proxxima systems in coating formulations is their ability to streamline application by replacing traditional three-coat services with a faster-curing single-coat solution. These systems also enable a reduction in volatile organic compounds (VOCs) and support excellent coating performance. When combined with APC’s TriFLEX™ technology, they deliver:

- Dry-to-touch in just 2 hours with full cure achieved in 12 hours—significantly faster than the 36-hour cure time of conventional coatings.

- Up to a 75% reduction in VOC emissions during application.

- Excellent impact resistance, UV durability, and corrosion protection—all in a single-coat direct-to-metal application.

- A high-build film with no sag at a 1 mm thickness.

In the Beaumont operation, Steel Painters Industrial applied the TriFLEX™ coating system using airless spray in a controlled shop environment. The results were impressive:

- Application time cut by more than half — reduced from seven days to just three.

- 30% increase in shop throughput — enhancing revenue potential.

- 20% reduction in material costs— including paint and thinners.

- 60% savings in labor and inspection costs — driving significant operational efficiency.

ExxonMobil plans to expand the use of coatings formulated with Proxxima systems across a range of applications—including storage tanks, insulated equipment, railcars, and marine vessels. Thanks to its versatility and high-performance characteristics, the resin system also shows strong potential in demanding services such as corrosion under insulation (CUI).

To learn more about Advanced Polymer Coatings, TriFLEXTM coating, and its high-performance coating systems, please visit https://www.adv-polymer.com.

Related content

What is Proxxima

Markets