ExxonMobil installs its first-ever section of Proxxima™ resin system-based MST-BAR™ at Plastics Plant in Mont Belvieu, Texas

The Proxxima GFRP rebar’s lightweight properties allowed for ease of use and speed of installation, while its durability promises lasting strength and lower lifetime costs.

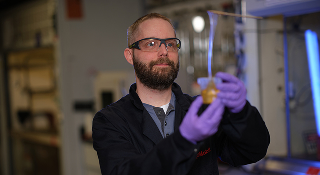

ExxonMobil successfully completed an installation demonstration of MST-BAR™, a Proxxima™ system-based glass fiber reinforced polymer (Proxxima GFRP) rebar, to replace and reinforce the heavily used roads of its Mont Belvieu plastics plant.

The project was finished in just three weeks, working with the company MST Rebar to develop a new version of Proxxima system-based glass fiber reinforced polymer (Proxxima GFRP) rebar. Mason Construction, a local civil construction team and ExxonMobil partner, handled the installation. The project represents the latest use of Proxxima™ systems in ExxonMobil’s own facilities and operations, in what has become a signature display of confidence in its product.

Combatting wear-and-tear of high-traffic areas

MST Rebar shipped 40,000 linear feet of material within a two-week window. “We had it in the ground a week later,” said Brian Cavaretta, Supervisor for the North Packaging and Shipping Unit at the Mont Belvieu plastics plant. “We’re pleased with the product and have no intention of going back to steel.”

The Mont Belvieu plastics plant has proven to be an ideal place to utilize the unique properties of Proxxima GFRP rebar, where a steady traffic of eighteen-wheelers and heavy machinery had resulted in significant wear-and-tear on the existing asphalt and steel-reinforced concrete paving. Additionally, the heavy rainfall of south Texas led to corrosion of the steel, resulting in an excessive amount of time and money spent annually on repairs and replacement.

Easier to transport, quicker to install

The MST-BAR™ created with Proxxima resin system proved lighter to transport, faster to install, and is expected to be more resilient in use. The crew was able to pre-tie the rebar, hand-carry mats and set it in place, without requiring heavy crane equipment, avoiding hot-work sparks.

“At first, I was skeptical just like anybody else,” said Trey Berry, Superintendent at Mason Construction. “But it's been a very smooth transition going from steel to something new that's a quarter of the weight – the MST-BAR™ with Proxxima. All in all, I think it should be the new standard.”

ExxonMobil is expanding use of Proxxima systems-based resins across other applications, including coatings for storage tanks, railcars, subsea pipes, and marine vessels. The company is demonstrating opportunities for cost savings, increased productivity, and enhanced safety.

Related content

What is Proxxima

Markets